Paper Bag Making Machine

Large Model Paper Bag Making Machine

Medium Model Paper Bag Making Machine

Standard Model Paper Bag Making Machine

Baby Model Paper Bag Making Machine

Paper Bag Making Machine

PAPER BAG MAKING MACHINE

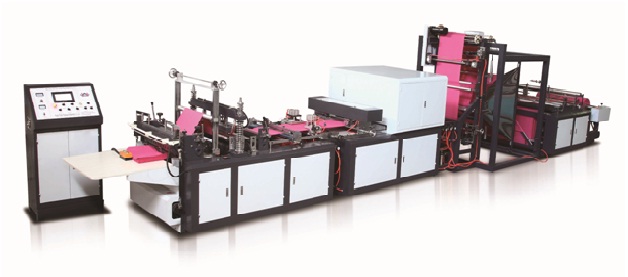

Owing to our expertise in the domain of paper bag making machine, we are able to offer technically advance and upgraded Paper Bag Making Machine. Our sturdy built machine wide applications in grocery sector requirements. Our machines are very good in speed and produce 100 -225 bags per minute. Our machines are easy to install, operate and need minimal maintenance. We have established very strong foothold in the market by offering most reliable and durable products at very reasonable prices.

PAPER BAG MAKING MACHINE IS DESIGNED TO MANUFACTURE FLAT AND SATCHEL PAPER BAGS FROM KRAFT PAPER, GREASEPROOF, WHITE PAPER AND POSTER PAPER ETC. IN DIFFERENT SIZE FOR PACKING CONFECTIONERY, FOOD STUFF, READY-MADE GARMENTS, TOBACCO, TEA POWDER GROCERY, DRY CLEANERS ETC.

We Have FOUR Models of Paper Bag Making Machines depends upon maxium and minium bag size.

You can change the bag size with help of size plate and gears. machine is equipped with 2 colour and 4 colourflexo printing unit to print the design and logo as per customer demand.

Specifications

| Specifications of Paper Bag Making Machine | ||||

| Model | Large | Medium | Standard | Baby |

| Max. Size of Bag | 42cm x 60 cm | 28cm x 50cm | 26cm x 36 cm | 15cm x 22 cm |

| Min.Size of Bag | 12cm x 18 cm | 12cm x 18 cm | 5 cm x 10 cm | 5 cm x 10 cm |

| Capacity per 8Hr. | 50-80,000 bags | 60-80,000 bags | 70-80,000 bags | 80-90,000 bags |

| Flexo Printing | 2,4 Colours | 2,4 Colours | 2,4 Colours | 2,4 Colours |

| GSM | 50-150 | 50-150 | 40-120 | 40-120 |

| MOTOR (HP) | 5 or 2 | 3 or 2 | 3 or 2 | 3 or 2 |

Paper Napkin Making Machine

We deal with Paper Napkin Making Machine, which is used to automatically fold the jumbo roll into the square or rectangular pieces. The offered machine also performs various tasks such as printing, embossing, counting, folding and cutting tissue papers.

Printing: 2 Colors Flexo Printing

Inner Core Diameter: 3″

Max. Unwinding Diameter: 40″

Width: 9″ x13″

Non-Woven Bag Making Machine

Product Introduction: This machine is suitable for non-woven fabric material, for making non-woven bags of different types and sizes like flat bag, shopping bag, gift bag, cloth bag, handle loop bag, vest bag, shoes bag, drawstring bags etc.

- This machine adopts Taiwan touch screen computer display, PLC computer program which can be edited.

- Auto meter counting & stopping, can freely set number.

- High voltage static processor, Auto constant temperature heating controller.

- Automatic punching.

- Unwinding magnetic power tension control with manual, auto side-correction control.

- This machine adopt ultrasonic welding of all aspects – bag mouth folding, welding, sealing-firm, beautiful and decent, side sealing etc. with high speed and efficiency. The machine is fast and easy to operate

Paper Plate Making Machine

Product Introduction: Paper plates are accessories that are used for serving food items at a regular basis. Be it a picnic or a finger food party, the role of paper plates can never be denied. Since these items are lightweight and can be easily disposed off, they are very convenient to be carried to any place for serving food items. These plates are available in a wide range of designs and sizes to meet the needs and preferences of consumers and an occasion or a picnic or an outdoor party in India is really unthinkable without the paper plates.

The products have many advantages and are hence preferred as compared to standard utensils/crockery for serving eatables. Additionally, because of the disposable nature, they save a lot of labor as far as cleaning/drying of utensils is concerned

Machines are available in single die, double die, triple die etc.

Quick Details:-

Model – Double Die Fully Automatic Machine Crank Model

Production – 45 pcs / per min.

Power Load – 1/2 KW (Single Phase)

Capacity of plate – 4’ to 12’inches

Paper Thickness – 100GSM to 180GSM

Weight of Machine – 450 kgs (approx)

Motor – 1hp

Power Consumption—2 Unit (Per Hour)

Paper Cup Making Machine

Product Introduction: A paper cup is a disposable cup made out of paper and often lined or coated with plastic or wax to prevent liquid from leaking out or soaking through the paper.It may be made of recycled paperand is widely used around the world.

Quick Details:-

Production – 50 to 55 pcs / per minute

Power Load– 3.5KW

Capacity of Cup – 50ml to 350ml

Paper Thickness – 180 GSM to 280 GSM

Weight of Machine – 1800 kgs

Motor – 3 hp (Single Phase )

Toilet Roll Making Machine

TOILET ROLL MAKING MACHINE

This hi-speed toilet paper toilet roll making machine is available in 810mm, 1020mm & 1650 mm working widths. It is slitting machine with perforation. Slitting blades could be adjusted to make Kitchen Rolls & Industrial rolls. Electronic counter is provided which controls the No. of sheets to be wounded over a given roll in this toilet roll making machine.

Features:

- Hassle free performance

- Low maintenance

- Low power consumption

- Rust proof body

QUICK DETIALS

Size :81 cm working

Slitting distance: 99 mm

Cutter : 8 Rotary Cutter with Holder & Bottom

Perforation : Repeat on 110 mm above

Motor : 2 HP DC Motor with

Maximum rewind : 200mm.

Speed : 1,500 to 2000 Rolls/8 Hrs/100gm..

Unwind Station : One

Weight : 1100 Kgs/approx.

Man Power : One Operator & 1 Packer

Raw Material : 14 to 26 Gsm.(2ply)

Maximum Unwind Dia : 1200 mm Max.

Dimension : 80″ L x 50″ W x 40″ H (Approx)

Aluminium Foil Rewinding Machine

ALUMIUM FOIL REWINDING MACHINE

Nowdays aluminum foil rewinding machine emerges as huge demand due to high demands of foil in almost every house, restaurant, hotel etcand also due to its less price and less maintaince.

Features of this machine:

|

Working width |

300mm Max |

|

Thickness of Aluminium Foil |

Min. 9 microne, max.20 Microne |

|

Electronic Control Panel |

1 HP DC MOTOR |

|

Length Counter |

With digital counter and sensor |

Production 900-1200 rolls per day ( 8 hrs) of 9m.

|

Thickness of Aluminium Foil |

Min. 9 microne, max.20 Microne |

Die Cutting Machine

Die Cutting Machine

Die Cutting Machine or Platen Punching & Creasing Press particularly designed for Die Cutting, Scoring and Creasing Work on PAPER, LINOLEUM, CARD-BOARD, CORRUGATED BOARD, FIREBOARD, CORK, LEATHER, PLASTIC AND PVC MATERIALS etc. Most Handsome and compact patronized Model requires Minimum Floor-Space. Minimum “Make-Ready” Time and provides sufficient hourly production

Basic Description

The very sturdy construction of Die Cutting Machine or Platen Punching & Creasing Press guarantees for perfect works under heaviest conditions.Frame, Platen & Main Gears made of special high tensile Cast Iron are resistant to deformation even if subjected to greatest strain. The platen is driven from the ball bearing mounted shaft through a pair of reduction spiral gears protected by guards.The main gear shaft and connecting arms are mounted on Phosphor Bronze bushes.The reduction gear shaft is made of hardened high quality alloy-steel. Lubricated counter- pressure elements prevent the gears from deviating under the work pressure.

QUICK DETIALS

Electromagnetic Clutch & Break System

Electromagnetic clutch & brake in Die Cutting Machine enables push-button control of the machine for easy and efficient operation. Complete safety is ensured by full electrical interlocking. Electrical synchronization of both the clutch and the brake eliminates the possibility of time lag or over-lag between driving & braking. Instead of Pedal Control, there is a clean panel within operator’s easy reach from where all machine operations can be controlled

Dwell Timing Device

This timing device in Die Cutting Machine can be set to give a variable period from 0.5 to 10 seconds. During this time the platen remains stationary in the open position before automatically resuming motion at the end of the set dwell period. This is a particularly useful feature where feeding work requires a fine register or when large or difficult sheets are being fed which would otherwise have to be run using the single impression procedure. This device can increase output to more than double that of a machine on single impression working and can also be of great assistance during the training of an operator.This model differs from pedal controlled machines being driven by Electro Magnetic Clutch & Brake Unit and Training Control Dwell.

Safety in the Machine

All moving parts on Die Cutting Machine are protected by approved safety guards. A special feature is the patented guard which protects the operator from the moving block. Should any object come between the moving block and this guard, a slight backward movement of the guard will occur stopping the moving block immediately and isolating the starting mechanism. Untill the Guard is moved forward by hand the machine remains dead and isolated from any attempt to actuate it through the starting mechanism.

|

Specifications of Die Cutting Machine |

|||||||

|

Inside Chase Size |

22″x32″ |

25″x37″ |

29″x40″ |

33″x43″ |

37″x51″ |

43″x63″ |

56″x76″ |

|

Platen Size |

25″x35″ |

28″x40″ |

32″x43″ |

36″x46″ |

40″x54″ |

46″x66″ |

56″x76″ |

|

H.P. |

3 |

5 |

5 |

7.5 |

10 |

10 |

15 |

|

Impressions per Hour |

1700 |

1500 |

1400 |

1300 |

1100 |

1000 |

800 |

|

Weight Approx |

3.4 |

4 |

4.5 |

5.4 |

6.5 |

9.5 |

13.5 |

Lamination Machine

LAMINATION MACHINE

Lamination machine are available in different models as HOT LAMINATION COLD LAMINATION in various sizes and we can manufacture machine as per demands also.

Quick details of standard model

|

Size : 24” |

24” (610 mm) |

|

Roll (Film) Width : 24” |

24” (610 mm) |

|

Roll (Film) Dia : 24” |

24” (610 mm) |

|

Power Reqd.: 1000 watts |

1000 watts (Single Ph.) |

|

Speed Max : 600 mts |

600 mts (1800 ft) /hr |

|

Dimension : 1800*1500*1950 mm |

1800×1500×1950 mm |